If you’re working with structural steel in Ireland, you’ve probably heard about intumescent paint. It’s one of those things that sounds complicated but is actually quite straightforward once you understand what it does. Basically, it’s a specialised coating that protects steel structures from fire damage, and it’s become pretty much essential for meeting Irish building regulations.

What Actually Happens When Intumescent Paint Gets Hot

Here’s the clever bit about intumescent paint for steel. When it’s exposed to high temperatures during a fire, the coating doesn’t just sit there like regular paint would. Instead, it swells up and forms a thick, foam-like char layer that acts as insulation. This char barrier slows down how quickly heat transfers to the steel underneath, which means the steel takes much longer to reach temperatures that would cause it to weaken or fail. That extra time can be critical for getting people out safely and giving firefighters a chance to control the blaze before the structure becomes compromised.

The whole point of using intumescent paint is to buy time. Steel on its own loses strength rapidly when it heats up, which is obviously a problem in a fire. By insulating the steel and keeping it cooler for longer, intumescent coating extends the fire resistance rating of the structure. This isn’t just good practice, it’s usually required by building regulations for commercial buildings, industrial facilities, and many residential projects.

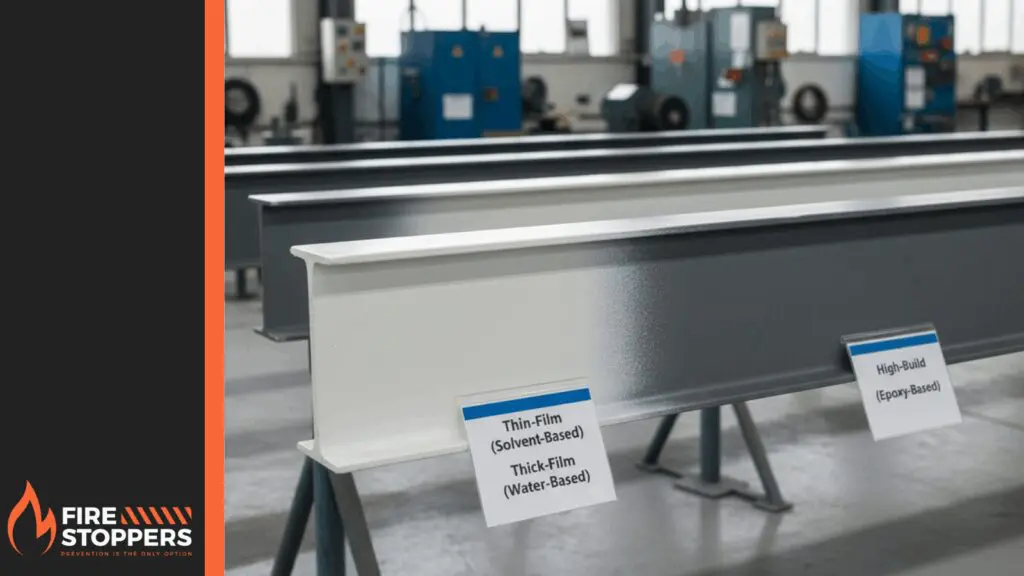

Different Types of Intumescent Coatings

When you’re looking at intumescent paint systems, you’ll typically be dealing with a few different components. Most systems include a primer that goes on first to help with adhesion and prevent corrosion, then the intumescent product itself (brands like Nullifire are common in Ireland), and finally a topcoat that protects the whole system and makes it look decent.

Thin film intumescent coating is probably what you’ll see most often on structural steel beams and columns. It’s popular because it does the job without looking industrial or ugly. You can get it in various colours, and once it’s finished with a topcoat, most people wouldn’t even realise it’s a fire protection system rather than just regular paint. The finish is smooth enough that it works fine in offices, retail spaces, and other areas where appearance matters.

Where You’ll Find Intumescent Paint Being Used

Walk through any modern commercial building in Ireland and there’s a good chance the structural steel you’re seeing has been treated with intumescent coating. It’s standard practice for steel beams and columns, especially in multi-storey buildings where structural integrity during a fire is absolutely critical. You’ll also find it in industrial facilities, warehouses, car parks, and anywhere else that structural steel needs passive fire protection.

The coating acts as a silent safety measure. It doesn’t need power, it doesn’t need maintenance beyond occasional inspections, and it doesn’t rely on anyone pressing a button or activating a system. When heat hits it, it just does its job automatically. That’s what makes it “passive” fire protection, as opposed to active systems like sprinklers that need to be triggered.

Getting It Applied Properly

The application of intumescent paint isn’t something you want to rush or bodge. Surface preparation matters quite a bit because if the steel isn’t clean and properly primed, the coating won’t adhere correctly and you won’t get the fire resistance you’re paying for. The steel needs to be free of rust, mill scale, grease, and anything else that might interfere with bonding. Once it’s clean and dry, a compatible primer goes on to create a solid foundation for the intumescent paint system.

Most contractors use airless spray equipment to apply intumescent coating because it gives you a uniform thickness across the surface. Getting the right thickness is crucial, actually. The fire resistance rating you achieve depends directly on the dry film thickness (DFT) of the coating. Too thin and you won’t meet the required fire rating, too thick and you’re wasting money on excess product. The manufacturer’s technical data sheet will specify exactly what DFT you need for different fire ratings, and that’s calculated based on the size and shape of the steel sections you’re protecting.

During application, the thickness gets checked regularly with a film thickness gauge. This isn’t optional, it’s how you verify that the coating will actually perform as intended. If any areas are reading too thin, additional coats get applied until you hit the target DFT. Once the intumescent paint has cured, a topcoat usually goes on to protect it from physical damage and environmental exposure, particularly if the steel is going to be exposed to weather or moisture.

Understanding Dry Film Thickness and Fire Ratings

Dry film thickness is one of those technical details that really matters when you’re specifying intumescent paint for steel. Different steel sections and different fire ratings require different thicknesses of coating. A small steel column might need less coating thickness to achieve 60 minutes of fire resistance than a larger I-beam would need for the same rating. The section factor, which is basically the ratio of the steel’s exposed surface area to its mass, determines how quickly it will heat up in a fire.

The required DFT for your project gets calculated based on the specific structural steel beams and columns you’re protecting, the fire rating demanded by building regulations (usually 30, 60, 90, or 120 minutes), and the product you’re using. Each intumescent paint manufacturer provides detailed tables showing what thickness you need for different scenarios, and these calculations need to be done properly during the specification stage.

Common Product Options

In Ireland, you’ll come across several brands of intumescent paint fairly regularly. Nullifire is widely used and has a good track record for both performance and availability. Firetex is another brand that shows up on specifications quite often. Thermoguard offers various intumescent products as well, and like the others, they produce technical documentation showing fire test results and application guidelines.

Water-based intumescent paint has become more popular recently because it’s less of a hassle to work with than solvent-based versions. Lower smell, easier cleanup, and better for both the applicators and the environment. The performance is comparable to solvent-based products for most applications, and you can still get different colour options and attractive finishes with the topcoat system.

Making Sure Everything Complies

Irish building regulations are quite specific about fire protection requirements for structural steel. Whether you’re working on a new build or refurbishing an existing structure, you need to make sure your intumescent paint system meets the required fire resistance rating for that building type and use. This usually means getting sign-off from a building control officer and providing documentation that shows the system has been applied correctly.

The protection system you choose needs to be tested and certified to European standards, with fire test data demonstrating it can achieve the ratings you’re claiming. Manufacturers provide this documentation, but it’s down to the contractor to apply the coating correctly and verify the DFT throughout the job. Keep good records during application because you’ll likely need to show evidence of compliance when the building inspector comes around.

Intumescent coating is one of those things that you hope never has to prove itself, but when it does, you’ll be glad it was specified and applied properly. It’s not the most exciting part of a construction project, but it’s definitely one of the most important for life safety and structural integrity during a fire.

Need Fire Safety Services?

Professional fire safety solutions for your peace of mind

Contact FireStoppers Today!

For Fire Emergency: Call 999 or 112

For all other fire safety services, use the contact details above